Benefits of Solid Fiber Push-Pull Sheets

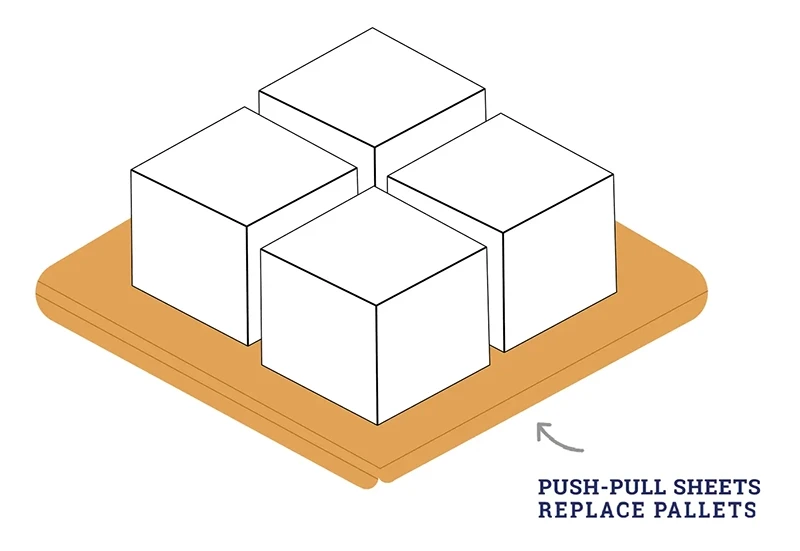

If you’re spending money on traditional wooden pallets, we can promise there’s a less expensive and more sustainable alternative.

Standard wooden pallets are the norm but aren’t always the best option. They take up more storage space and are heavier. And protruding nails and splinters can cause serious product damage or injuries.

The good news is, there is a solution.

Solid Fiber Push-Pull Slip Sheets from Badger

Our solid fiber push-pull slip sheets are the perfect alternative to traditional pallets because they are:

- Thinner and lighter than wooden pallets

- Less expensive

- Able to handle heavy loads

“Storing products on push-pull sheets saves you crucial space since they’re so much thinner than pallets,” said Scott Kibler, Vice President of Solid Fiber & Technical Products. “And that also means less warehouse space for the same amount of product.”

We also custom-produce all orders, so you’re getting a product cut to the exact specs you need.

Another benefit: Space savings. Wood pallets can cost upward of $15 apiece. Our push-pull slip sheets generally cost $2-$3 per sheet and are available in the quantity you need – not only full truckloads.

By swapping out wooden pallets for push-pull slip sheets, you’ll save money without sacrificing efficiency.

Sustainability and Badger

As with all our products, sustainability is a key focus in our push-pull sheet product line.

Our sheets start with virgin fibers, which are selected for their strength and durability. Once we’ve cut the sheets from the main roll, any extra pieces are gathered, baled, and returned to the mill. In a year, we recycle more than one million pounds of paper.

Sheets are durable enough for many uses. Afterward, they are fully recyclable through any curbside program.

Let Badger Help You Choose

Need help evaluating the best product transport solutions? We’re here to help you evaluate your current process and see how our chipboard products, including push-pull slip sheets, can help you.

Scott, who has decades of experience in the solid fiber and packaging industry, can help you pick from numerous substrates to suit your project needs and budget. We can also test your current products for durability and quality and make recommendations on where these can be improved.

We offer fast quotes from coast to coast — so contact us today for yours!