Thank You!

While many packaging substrates can be recycled, many aren’t. The reason? It might depend on your local recycling program or service.

Chipboard is different. Not only is it made from recycled material, but it can also be recycled again after use, making it one of the most sustainable packaging options. Keep reading to learn more.

The answer is simple: Yes! Chipboard can be recycled even from your regular curbside recycling program.

At Badger, we’re conscious of our products’ sustainability from end to end. Our initial chipboard stock is a recycled product, and any scrap we use in the plant is also recycled into more chipboard.

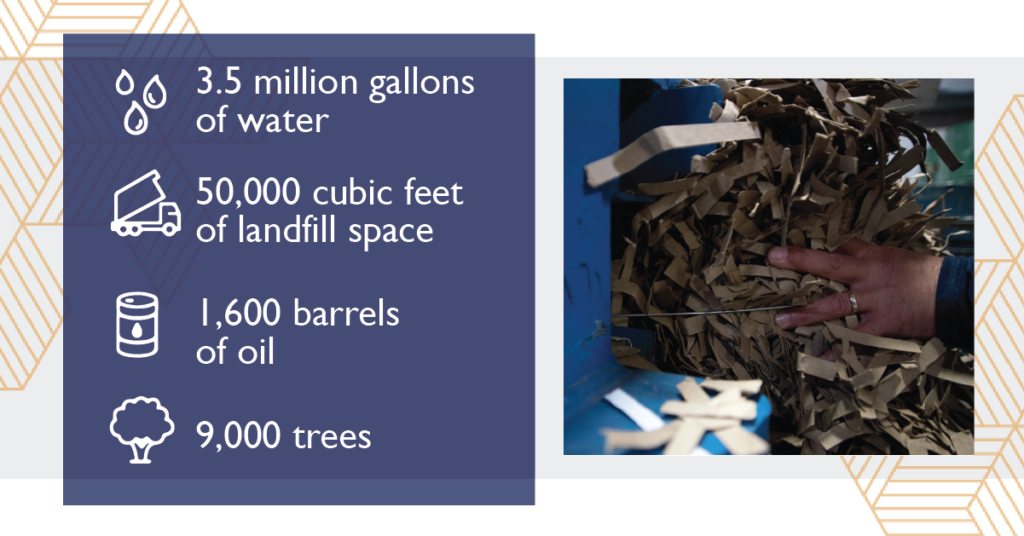

In the course of a year, we recycle over a million pounds of paper, saving:

By contrast, plastic packaging production requires large quantities of nonrenewable petroleum. Worse, not all plastics can be recycled or reused. From a sustainability perspective, paper is a smarter choice.

“If everybody plays their part in going from a plastic product to a chipboard product, you can really make a big impact,” said Chad Kravick, vice president at Badger Paperboard.

Paper-based packaging can do just about anything plastic can — and often at a better price.

Whether it’s pallet sheets, guards or pads, using chipboard packaging for your shipping needs is a sustainable and economic solution. And if you need a custom option, we’re happy to work with you to find a product that fits your needs.

With four plants located across the country, you can rest assured that Badger will have the supplies you need — on time, every time.

Our Badger Promise means you can expect fast turnaround times, responsive service and custom products with each order.

Curious to see what chipboard can do for you? Request a product sample today to get started.