Thank You!

The world of pet food has been booming lately, but the rapid growth brings fresh challenges. As consumers start demanding more transparency, more options and more innovation, pet food manufacturers have to become nimbler and more creative with everything from ingredients to shipping solutions. Some of our core chipboard products have been helping these businesses find ways to adapt to the changing landscape.

Pallet Sheets defend bagged products against splinters, nails, bugs and (eek!) mice. By keeping damage at bay, pet food manufacturers can reduce product loss in storage and during shipping. Without the scuffs, scratches and tears from an unprotected pallet, bagged products arrive at the retailer looking ready for the shelf, not the dumpster.

Perfect for preventing bumping, chipping, slipping and breaking, chipboard dividers can be custom fit to any package. Many of our customers use them to keep canned foods from sliding around or to separate stacked products within smaller boxes. Divider sheets can also serve as layer sheets between tiers of products, stabilizing loads of canned dog food, bagged kibble, or anything else that needs to make the journey safely.

What’s the fun in a doggie bone if it doesn’t look anything like a bone? Unfortunately, the shipping process has a way of turning dog treats into crumbs. Custom-cut chipboard dividers can protect biscuits and other treats from the rough and tumble trip to the store. Badger’s unique die-cutting system allows us to cut dividers into any shape and size (including dog bones!) with top-notch accuracy. When a perfect fit really matters, die-cutting is an ideal way to get dividers cut to your precise dimensions, every single time.

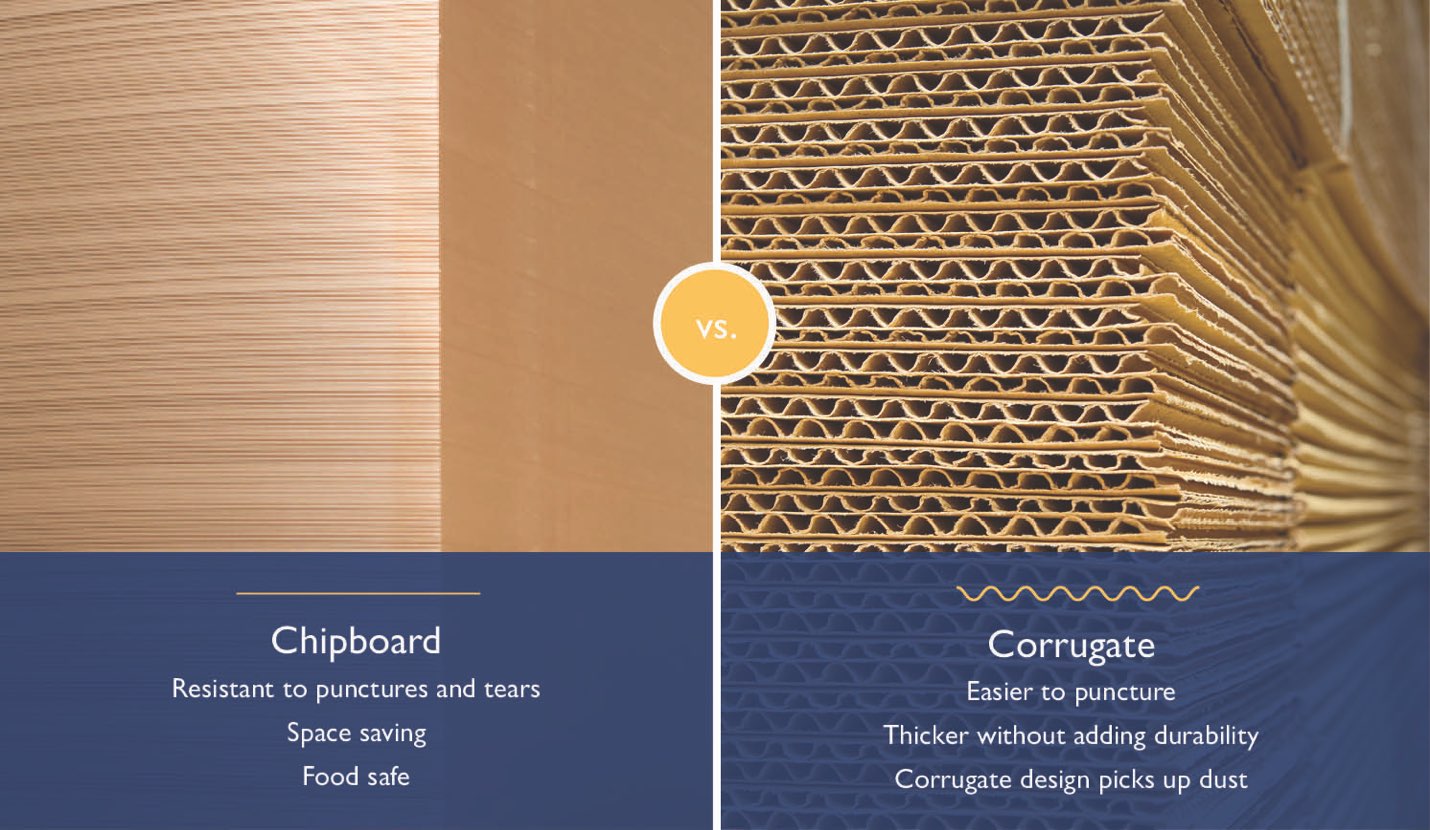

Warehouses across the country are making the switch from pallets to push/pull sheets. Why? For transfers that happen within the warehouse, push/pull sheets are lighter, thinner and more affordable than old-school pallets. Pet food manufacturers can save a heck of a lot—both in budget and in warehouse space—by going with chipboard. To imagine how big of a difference chipboard could make, picture how much of your warehouse would be filled by 3,000 pallets. It would be racks and racks, right? Well, 3,000 chipboard sheets would fill one single pallet. That’s some serious space saving. Even if you’re using corrugate right now, chipboard can still free up some space—12,000 corrugate sheets would fill a whole truckload, but in chipboard that’s just 4 pallets.

Like the food we eat, animal food is regulated by the U.S. Food and Drug Administration. The FDA requires that all food for your furry friends “be safe to eat, produced under sanitary conditions, contain no harmful substances, and be truthfully labeled.” That means that pet food manufacturers, shippers and distributors have to do their research when they select vendors—not only for the ingredients in their products, but also for their shipping and packaging materials. At Badger, our facilities are sparkling clean and certified to produce food-grade shipping solutions, so every order from us is ready to meet the FDA’s regulations for pet food.

Want to learn more about how Badger can help your business keep pace with customer demands? Give us a call.