Thank You!

Versatile, lightweight and cost-effective, chipboard makes an affordable replacement for corrugate in many shipping and packaging applications. Here we’re focusing on Pallet Sheets, but we’ll be talking slip sheets, push/pull sheets and more in a later post.

Shipping can be a rough business—products get scraped, poked and bumped around as they move through warehouses, on trucks and trains, and on to their final destinations. A pallet sheet protects your products from nails, splinters or dirt on the pallet. But it also defends products from anything that may poke through the spaces between pallet slats. And while we may not want to think about it anything creepy-crawling around your products, pallets sheets are an important protection also protect against bugs and other critters.

Bagged products are especially vulnerable to damage during shipping. Imagine tearing a hole

in a bag of ice melt or dog food—you’d have a serious mess on your hands. Plus, every lost product is a loss for your bottom line. That’s where chipboard pallet sheets come in.

They are ideal for manufacturers and distributors in the pet food, lawn and garden, food and beverage, and any other industry that relies on bagged products to keep their business moving.

Pallet sheets are also important for consumer products that need to arrive looking ready for store shelves. Beauty items, groceries and other CPG products should all be protected from dirt and damage by a chipboard pallet sheet.

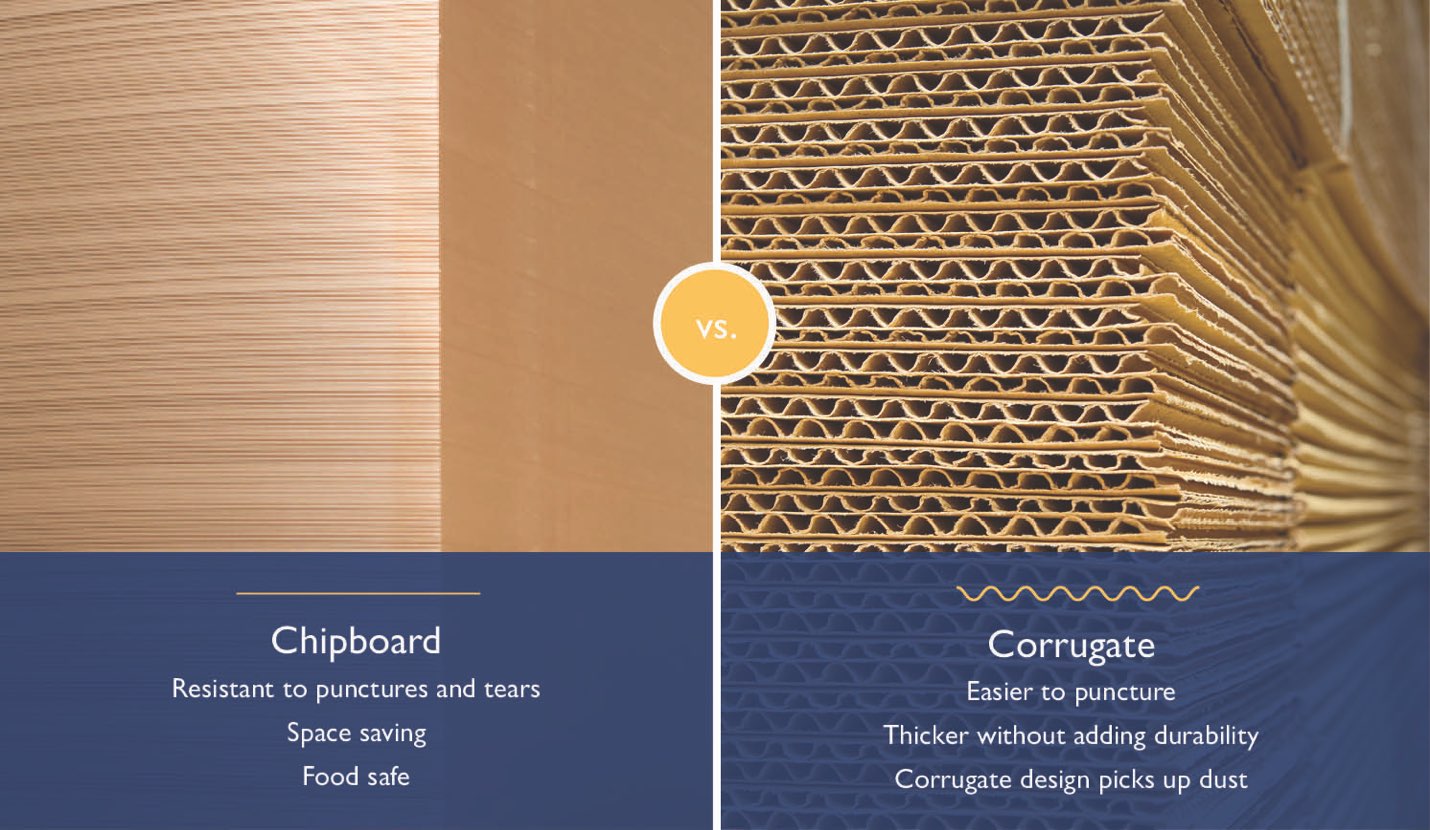

We thought you’d never ask. While pallet sheets can be made from traditional corrugate

or chipboard, there are big benefits to choosing chipboard pallet sheets.

#1: Chipboard pallet sheets are more resistant to punctures and tears.

#2: Chipboard is also thinner than corrugate: the number of sheets on a whole truckload of corrugate could fit on just 4 skids of chipboard.

#3: Unlike corrugate, chipboard can be rated as “food grade,” meaning it is safe enough to be used for transporting food and beverage products. Why? That recognizable “wavy” layer of corrugate creates channels that pick up dirt and dust—which can be a big problem when dealing with food.

With a variety of thicknesses, materials and sizes available—including the standard

48”x40”—it’s important to choose the right pallet sheet for the job. If you’re in the market

for pallet sheets, request a quote and our Badger Paperboard team will help get you exactly

what you need.